Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

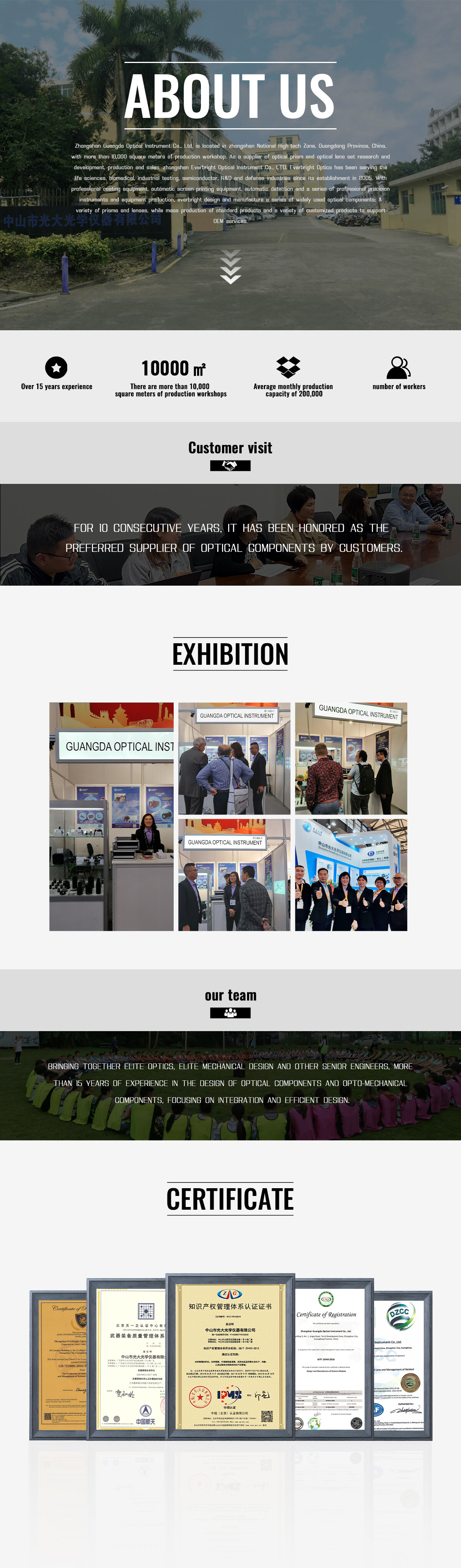

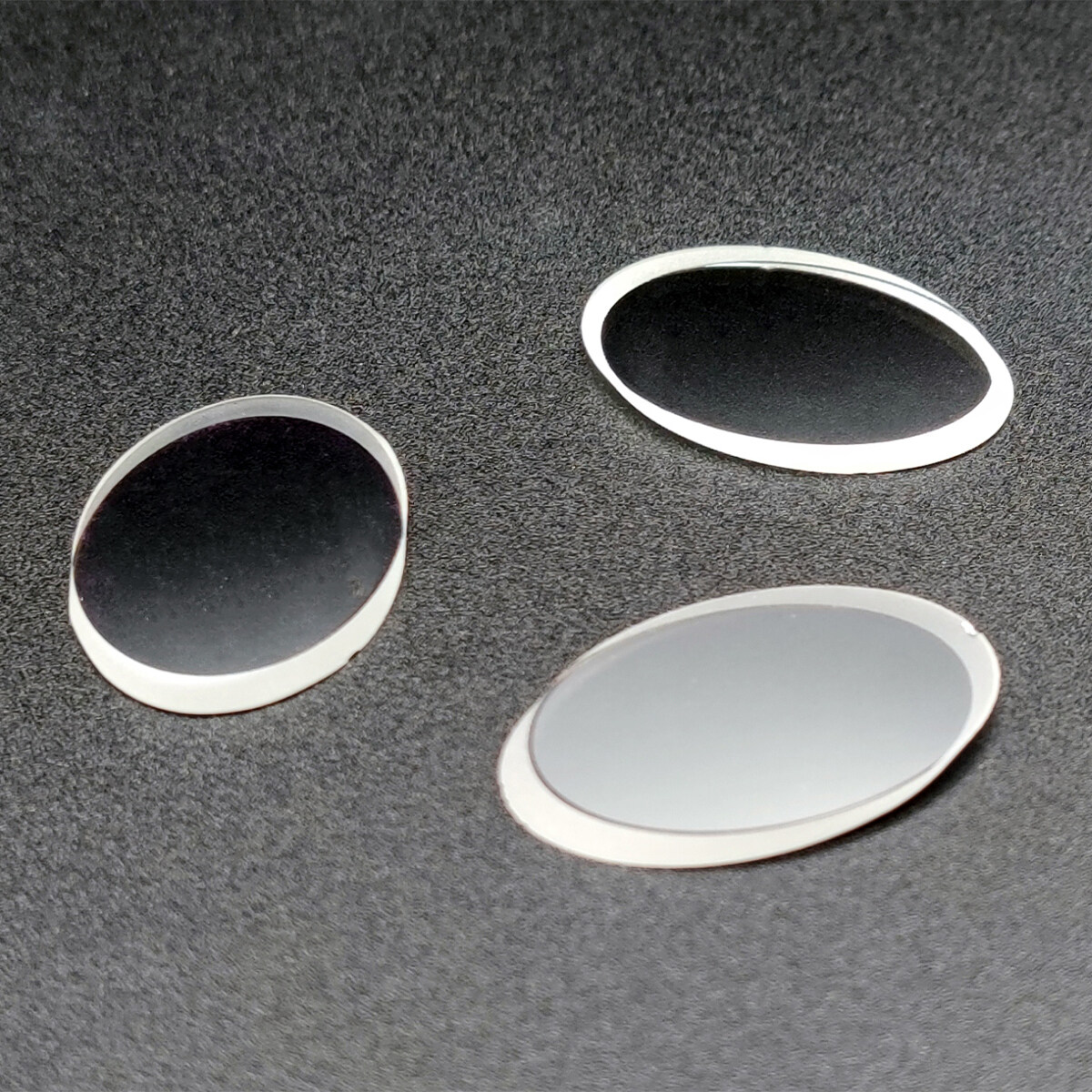

Polarization Spectroscopy Film

We are one of offiber optical polishing film filter supplier manufacturers in China.The optical beam splitter is an optical thin-film filter that divides the beam into two parts according to certain requirements and certain ways.If you need this film,welcome to contact us.

What is an optical spectroscopic film?

With the continuous development of science and technology, the optical industry also has a new development. Optical filters, optical coating, and other industries are also developing rapidly. In the optical industry, professional terms such as optical coating and optical spectroscopic film are often heard. What are these? Today, let's take a look at what is optical spectroscopic film. What is an optical spectroscopic film?

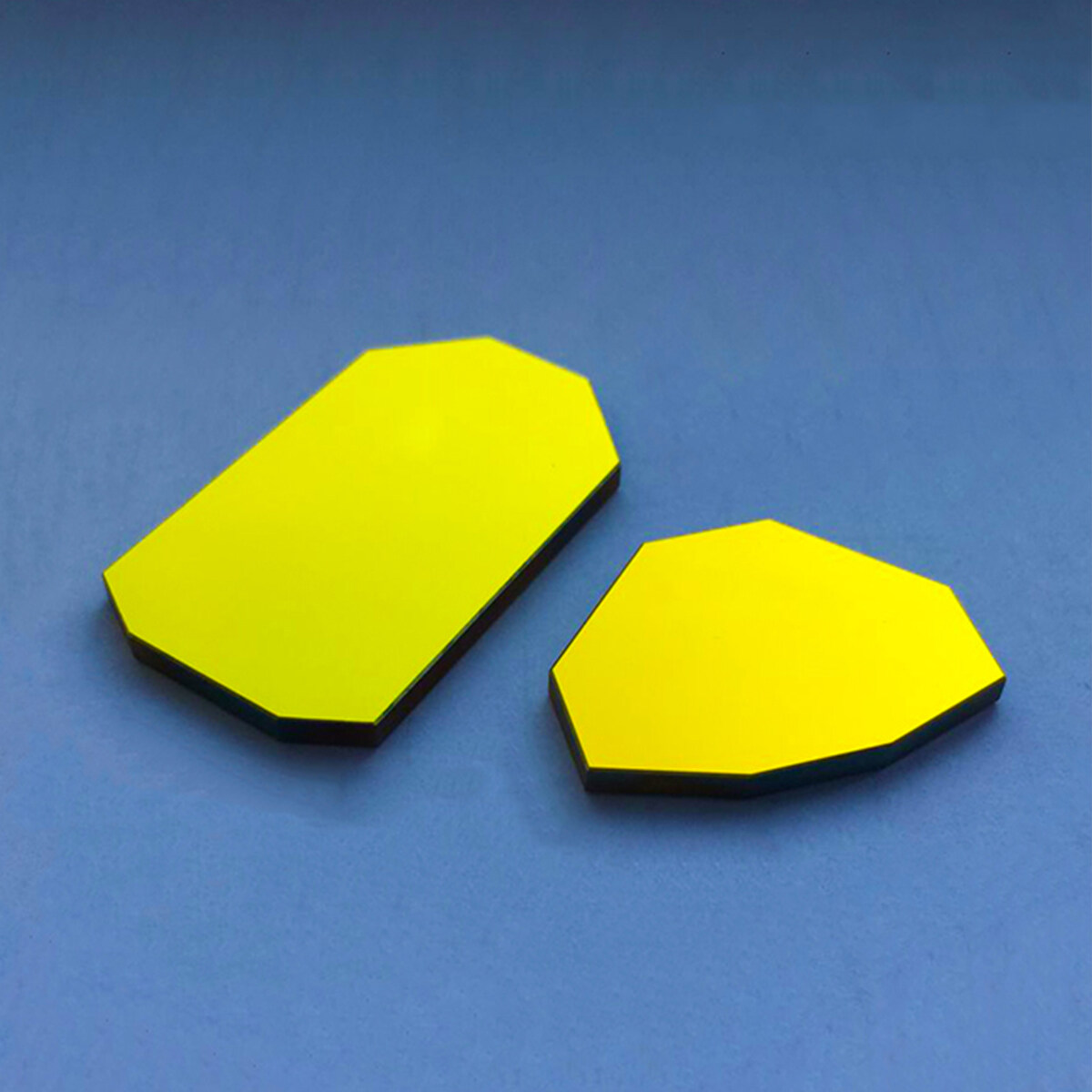

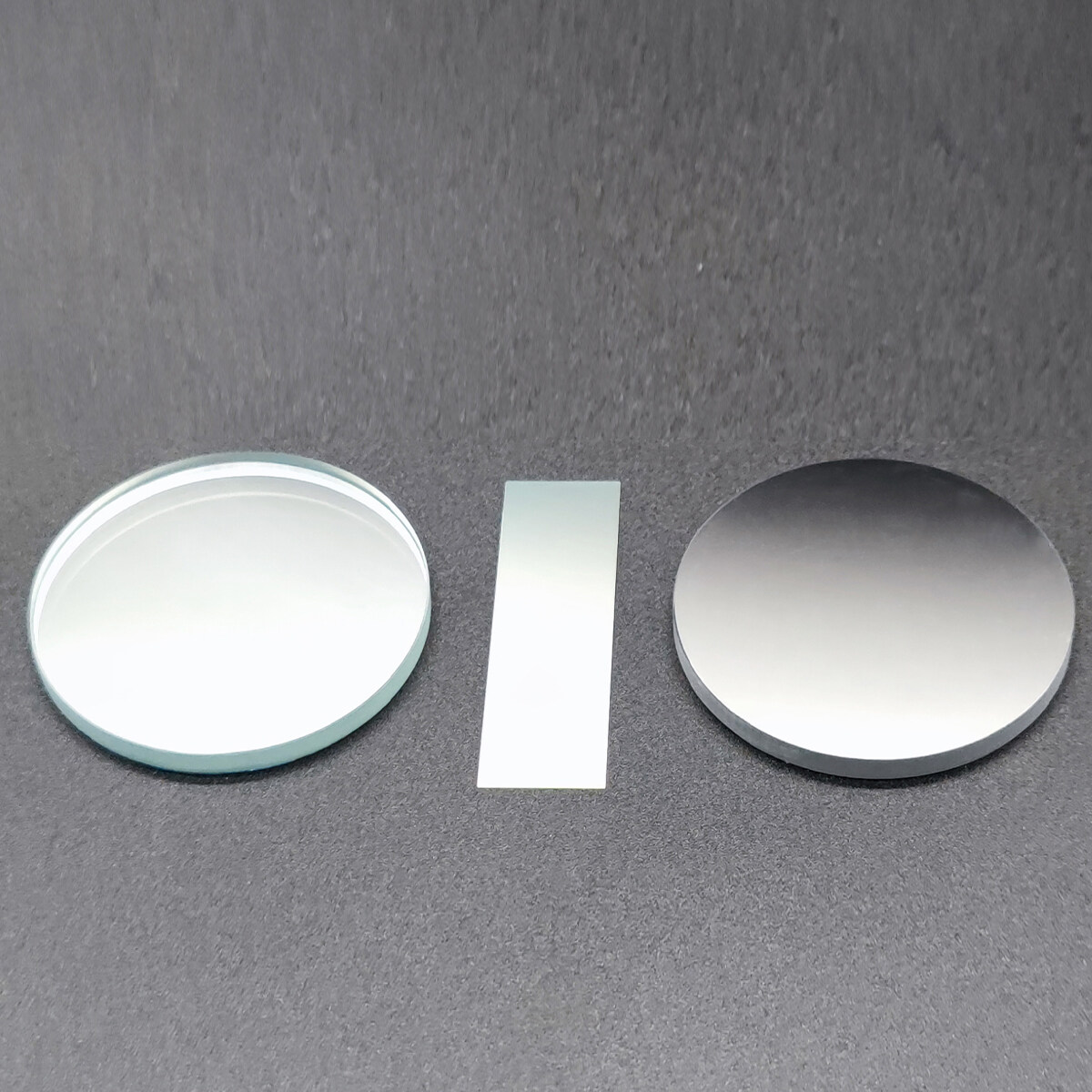

The optical beam splitter is an optical thin-film filter that divides the beam into two parts according to certain requirements and certain ways. Optical spectroscopic films mainly include wavelength spectroscopic films, intensity spectroscopic films, and polarization spectroscopic films.

What is a polarization spectroscopic film?

Polarization spectroscopic film is made of the polarization effect of the thin film when light is incident obliquely. Polarization spectroscopic film can be divided into prism type and flat plate type. The prism-type polarization film utilizes the polarization effect of the interface when the Brewster angle is incident (see the refraction and reflection of light on the interface).

When the beam is always incident on the interface of two materials at Brewster angle, the reflected light of horizontal vibration is always zero regardless of the number of film layers, while the light of vertical component vibration increases with the increase of the number of film layers. As long as the number of layers is enough, the transmitted beam is the light of parallel vibration, and the reflected beam is basically the light of vertical vibration, so as to achieve the purpose of polarization and light splitting, Since the Brewster angle on the interface of the two thin film materials cannot be reached by air, the thin film must be plated on the prism. At this time, the incident medium is not air but glass.

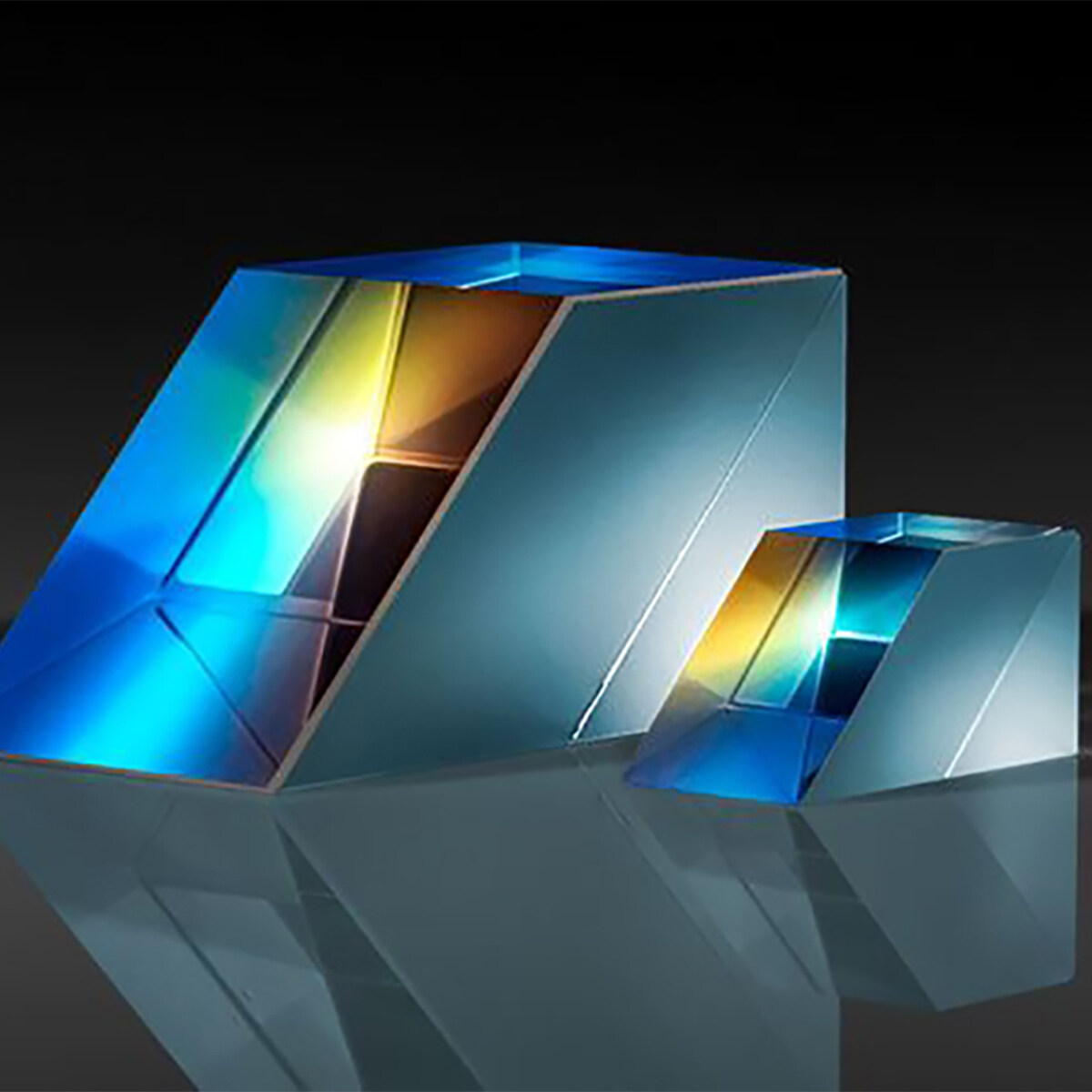

The plate-type polarization film is mainly made by using the difference in the reflection bandwidth of the two polarization components of the dielectric reflection film at oblique incidence. Generally, with the increase of the incident angle, the reflection bandwidth of the vertical component gradually increases, while the bandwidth of the parallel component gradually decreases.

Selecting the high reflection area of the vertical component and the high transmission area of the parallel component as the working area can form a polarization film that reflects the vertical component through the parallel component. The incidence angle of this polarization film is generally selected near the Brewster angle of the substrate. The prismatic polarizing film works in a wide wavelength range, and the degree of polarization can also be made relatively high, but its preparation is troublesome, it is not easy to be made large, and the anti-laser intensity is relatively low. The plate polarizer works in a narrow wavelength range, but it can be made very large and has high laser resistance, so it is often used in high-power laser systems.